A complex of locksmith and installation works for the maintenance of bolted (threaded) connections at the customer's facilities. Certified and high-tech equipment is used to perform the work.

Controlled bolting

Execution of works with hydraulic torque wrenches, stud tensioners, torque wrenches

Uniform tightening of the flange connection with torque control up to 150,000 Nm

Installation/disassembling of a threaded connection of various types and in sizes of nuts from 12 mm to 165 mm

Unscrewing studs up to M150 in size without damaging the thread

Working in a short time - reducing the downtime of equipment during its maintenance

Reduction of labor costs

Torque control - better tightening of threaded connections

High-precision and uniform fitting minimizes the likelihood of leakage of flange connections. This avoids unplanned production shutdowns

Safety of work and preservation of the integrity of fasteners

Adaptability to conditions - we work with hard-to-reach threaded connections and take on atypical bolting tasks. If necessary, it is possible to calculate the recommended tightening torques

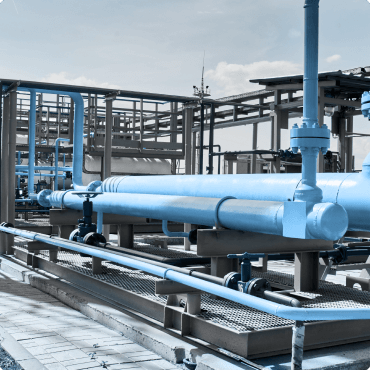

Oil and gas fields

Drilling platforms

Gas compressor stations

Furnace and crushing and screening equipment at cement plants and quarries

Installation of tower cranes, bridge trusses on construction sites

Heat exchangers and column equipment at oil refineries and chemical enterprises

Repair of equipment in ports at shipbuilding and ship repair plants

Uniform tightening with torque control (error no more than 3%) of equipment from 48 to 150,000+ Nm

Installation and disassembly of fasteners with nut sizes from 12 to 165+ mm

Hydraulic Torque Cassette Wrenches

Hydraulic Torque End Wrenches

Hairpin tensioners (tensor jacks)

Manual dynamometer tool