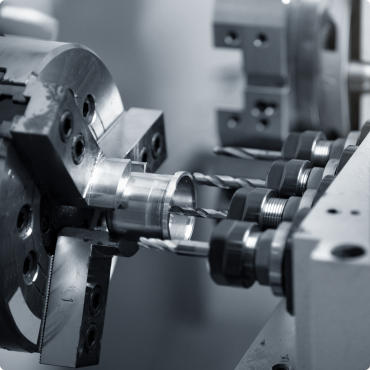

Work on the springless cutting of pipes of various diameters and simultaneous chamfering. The use of high-speed steel cutters and portable metalworking machines is applied.

Fireless pipe cutting

Processing range from 20 to 1448 mm

Pipe strength class K100

Wall thickness up to 100 mm

Various grades of steel, including heat-resistant and stainless

Chamfering of various profiles (set by the geometry of the cutting tool)

Pipe cutting with simultaneous chamfering (on pipes with an open end)

Internal boring of pipes (using a boring module at a depth up to 254 mm)

Pipe boring in the axial direction (using the axial feed module)

Cutting and processing of oval pipes (with the possibility of compensation of ovality up to 25.4 mm)

Various types of drives (hydro-, electro-, pneumatic), in explosion-proof design

Adaptability to conditions - performing work in hard-to-reach places (minimum installation space starting from 115 mm), installation on a continuous section of the pipeline (including bends, tees, transitions, etc.), cutting and chamfering with minimal offset from the end

Cutting of pipes with residual product content in the pipeline.

Pipeline laying - pipe cutting to size and preparation for welding

Cutting of defective sections of the pipeline and repairing of defective welded joints in accordance with STO Gazprom

Preparation of edges for welding to insert a new coil

Preparation for welding of pipes of different thickness, connecting parts of pipelines